Biocidal products, such as disinfectants and sanitisers, are commonly sold as concentrates that need dilution before use. Concentrated disinfectants can reduce cost, but present increased risks, and training to ensure they are correctly diluted before use is essential. The correct dilution rate ensures the product’s efficacy while maximising its value. Using the right dilution is crucial to both health and safety. This blog post examines the risks and commonly made mistakes when diluting disinfectants, as well as giving you some tips to ensure your team is safe and protected from infection.

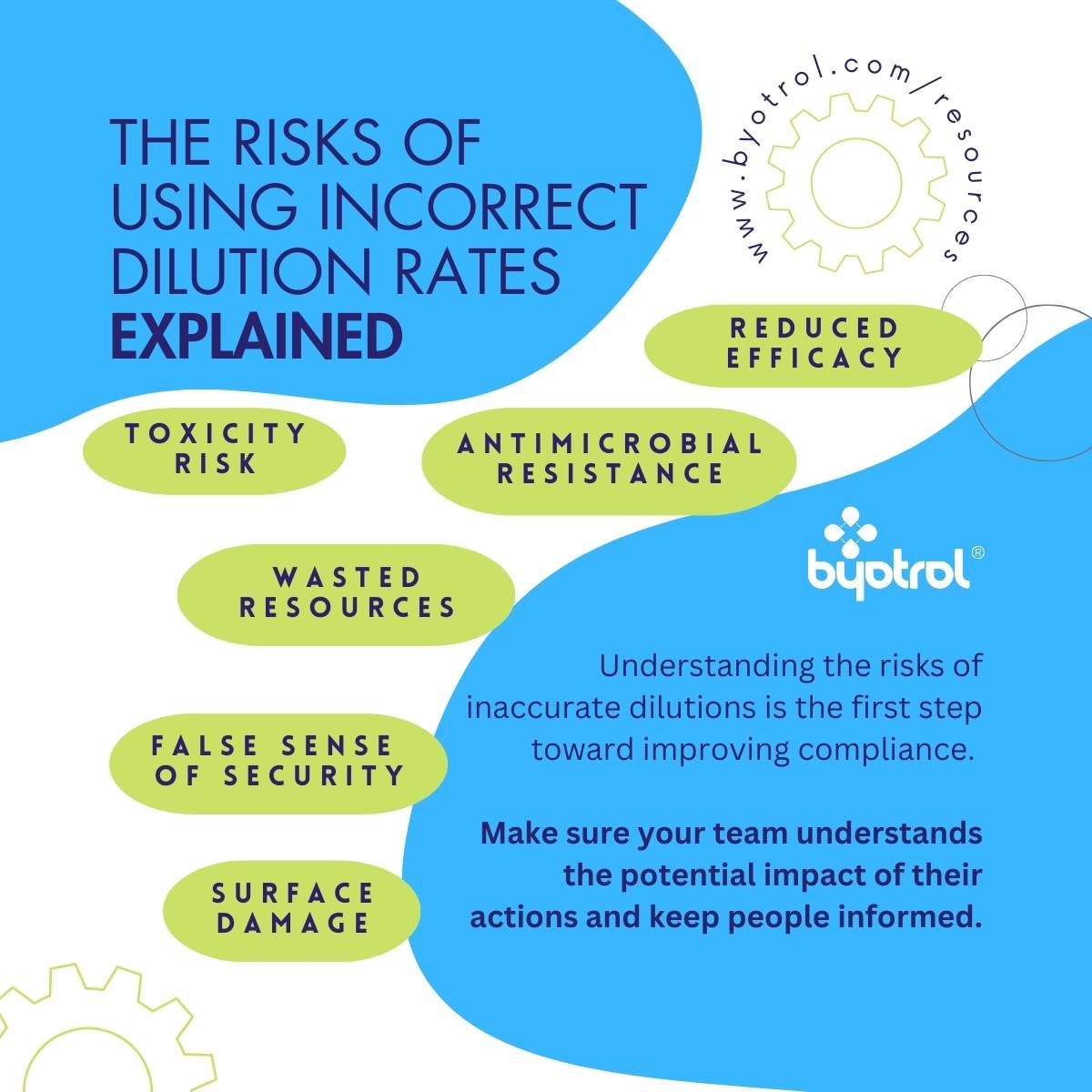

Risks of Incorrect Dilution

Understanding the risks of inaccurate dilutions is the first step toward improving compliance. Make sure your team understands the potential impact of their actions and keep people informed.

Over-dilution: (too weak)

Reduced Efficacy: Not enough biocide to eliminate or control your target pathogens and non-compliance with agreed protocols.

False Sense of Security: Surfaces may appear clean but could still harbour harmful microorganisms.

Waste of Resources: Money and time spent cleaning to produce sub-optimal results.

Antimicrobial Resistance: Exposure of microorganisms to sublethal levels of disinfectant can increase the risk of biocidal-resistant microorganisms.

Under-dilution (too concentrated):

Toxicity Risk: Higher concentrations can be harmful to humans and animals, potentially causing chemical burns or respiratory issues.

Surface Damage: Concentrated disinfectants can corrode or degrade surfaces, including metals, plastics, and fabrics. They are commonly tested for surface compatibility at specific dilution rates.

Wasted Product: Using more concentrate than necessary means you’ll run out faster and spend more, it also releases excess biocides into the environment.

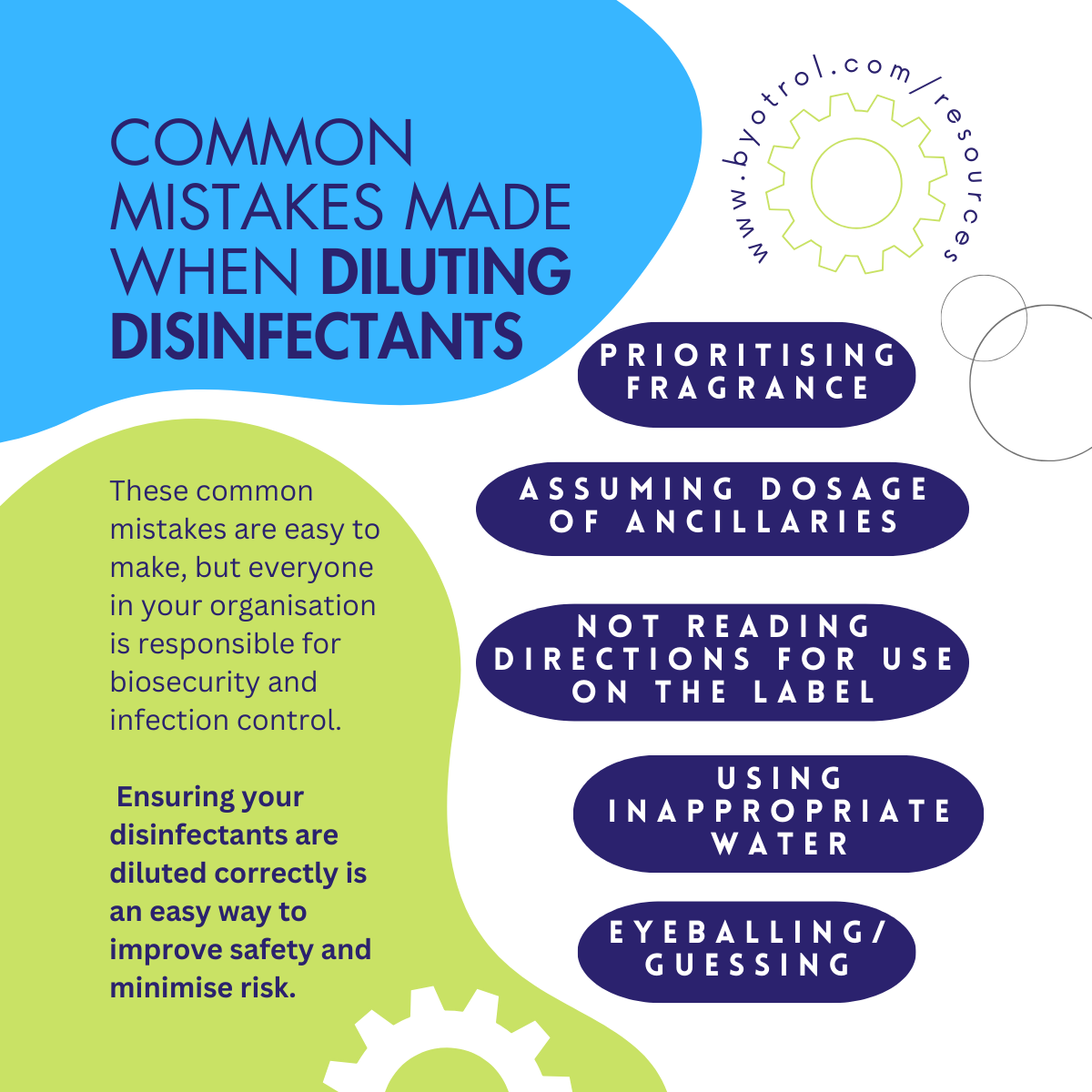

Common Mistakes Made When Diluting Disinfectants

These common mistakes are easy to make, but everyone in your organisation is responsible for biosecurity and infection control. Ensuring your disinfectants are diluted correctly is an easy way to improve safety and minimise risk.

Eyeballing: Guessing the amount rather than using precise measurements is not a reliable way to measure chemicals.

Prioritising Fragrance: Adding more or less concentrate to achieve your desired fragrance level might make your workplace smell nice to you but stick to your agreed protocols to keep your team safe.

Assuming Dosage of Ancillaries: Pelican pumps that attach to larger containers of concentrate can vary in their dosage, always check with the manufacturer.

Not Reading Instructions: Each product may have different dilution requirements, never assume different products share dilution rates, especially if it is a different brand.

Using Inappropriate Water: The quality of water (e.g. hard or soft) can affect dilution and efficacy, and some disinfectants require dilution with purified water instead of tap water.

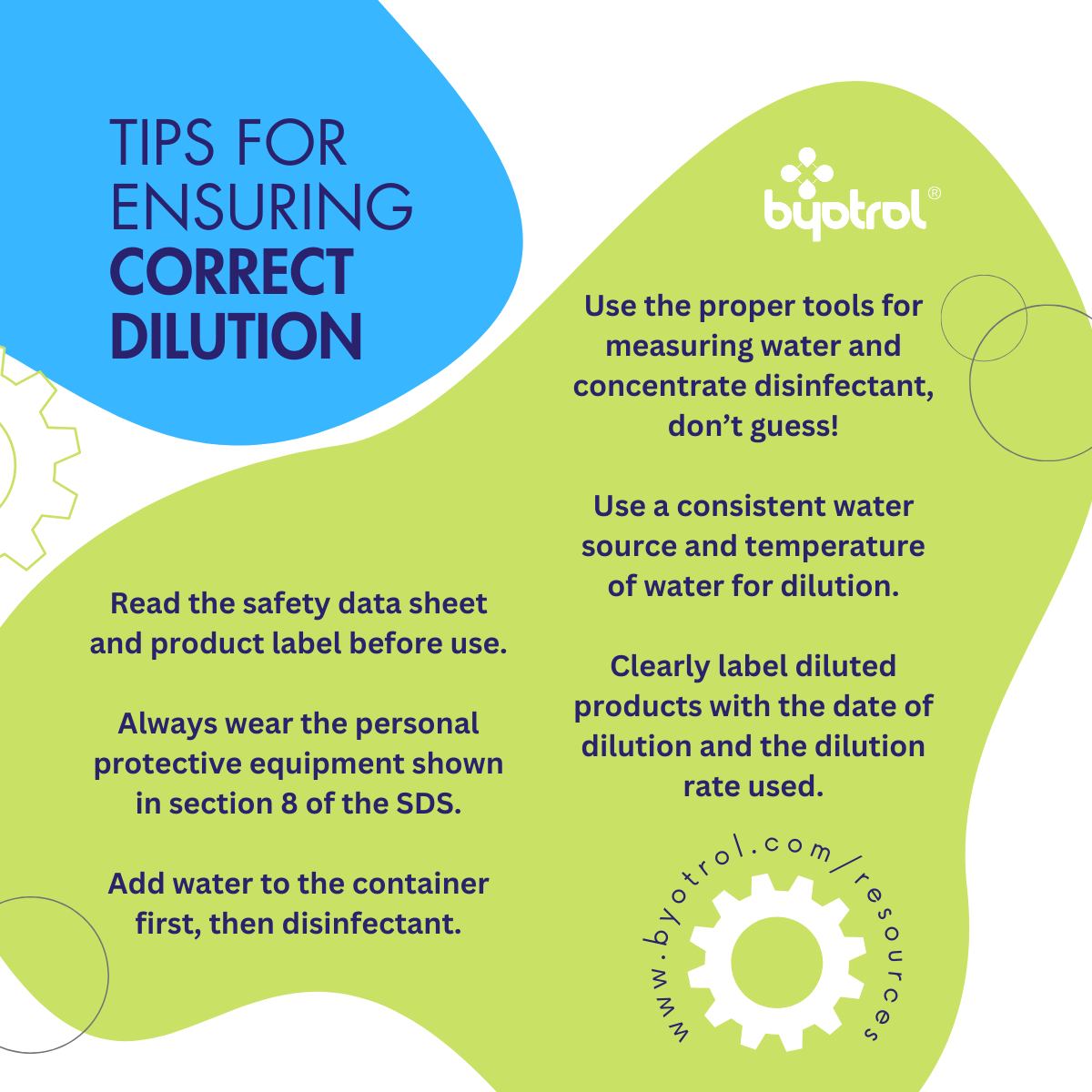

Tips for Correct Dilution

Here are our team’s tips for ensuring consistent and accurate dilution of disinfectants.

Safety First: Consult the safety data sheet before diluting products and always wear the personal protective equipment stated in section 8 when handling concentrated products.

Read the Label: Always follow the manufacturer’s guidelines for dilution rates and ask your manufacturer for posters that can be displayed in working areas to remind you of the correct dilution rates.

Use Proper Tools: Use measuring cups, graduated cylinders, or automatic dilution dispensers for accurate measurements.

Consistency: Always use the same source and temperature of water for dilution, ask your manufacturer for guidance if you are unsure.

Add Water Before Disinfectant: Always add water to your container first, then the disinfectant, this helps to reduce the risks of splashback of concentrate disinfectants into your face.

Store Safely: Keep concentrates away from children and animals. Clearly label diluted products with the date of dilution and the dilution rate used, Byotrol’s colour-coded dilution stickers are designed for this purpose.

Regularly Review: Periodically refresh your knowledge of the products you use and their dilution rates. Ask your manufacturer for their training resources for your team and incorporate them into your team training sessions.

Using the correct dilution rate for biocidal products is crucial for health, safety, and effectiveness. By understanding the risks and following the recommended guidelines, you ensure a clean, safe, and efficient environment.

Register for access to Byotrol’s Resources portal which contains downloadable training materials, dilution posters, and user guidelines to help your team dilute our products accurately and safely.